Plstic Building formwork

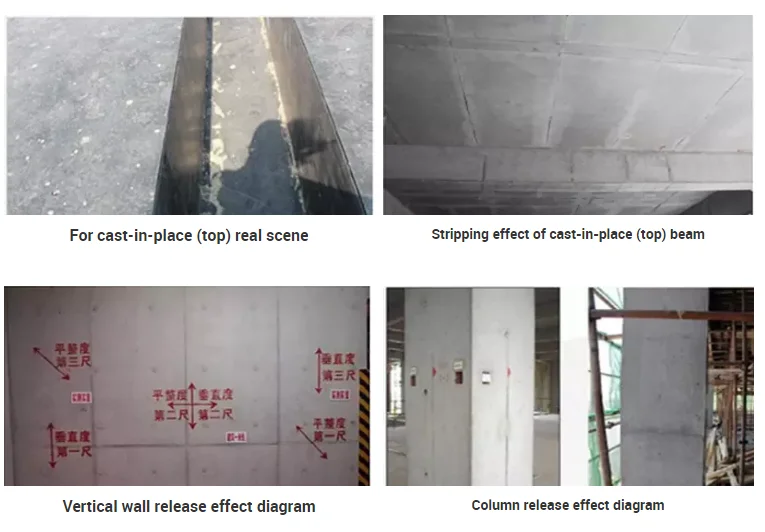

The surface of the plastic formwork is glossy, which can meet the requirements of clear water concrete formwork. The demoulding is quick and easy.It is easy to control the flatness error of plastic formwork's surface.The thickness of plastic formwork is uniform, and the tolerance can be controlled to ±0.3mm.

The plastic formwork has good acid and alkali resistance and water resistance. It don't delaminate and decay if it is immersed in water for a long time. The water swelling ratio of the material is less than 0.06%, and the size is stable. It is resistant to acid, alkali and corrosion,and also maintain functional in extreme environment.

1. Light weight, high strength, good toughness and strong shock resistance ability

2. Small expansion coefficient, large plate width, less joints and wear resistance

3. no moisture absorption, no mildew, no cracking, cold resistance, high temperature resistance, acid and alkali resistance

4. easy to process, can be sawed, nailed, weldable, vertical and horizontal can be arbitrarily connected and combined

5. the surface is smooth: casting effect is good

6. the turnover can be used more than 50 times, and the service life is long

7. easy to demould, no need to brush the release agent, tap the template to fall off, shorten the man-hour saving manpower and speed up the project

8. Environmental protection, energy saving, no pollution, no harmful or toxic gas emissions

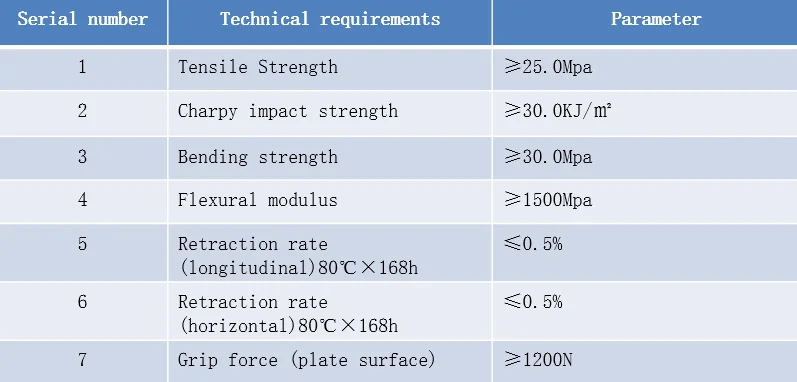

Hollow plastic building formwork product parameters

Comparison of various formwork performance and parameters

Construction characteristics of hollow plastic building formwork

★Easy to support and dismantle the construction formwork

Hollow plastic building formwork surface is smooth, automatic demoulding, no need for cleaning and maintenance, no need for release agent, the surface of the formwork after use is not sticky cement, the formwork does not need to be cleaned; under the same workload, the construction efficiency can be increased by 40% compared with the steel formwork. Compared with bamboo and wood formwork, the construction efficiency can be increased by 40%.

★ it is convenient and safe to move the construction formwork

The density of the hollow plastic building formwork is 0.4 g/cm3, which is 1/21 of the steel, light in weight, and easy for workers to carry. The formwork will not be deformed during use, which can greatly improve the construction safety, and the damage rate is less than 1‰.

★ Save time to assemble the construction formwork

Can be customized to the extent, without the need to process the same building area on site, hollow energy-saving building formwork save about 40% more time than traditional formwork.

★it takes a short time to disassemble the construction formwork

The thermal expansion coefficient of the hollow plastic building formwork is far from the concrete. After the pouring is completed, it will be automatically separated from the concrete with the change of temperature. It can be easily removed without tapping, and the working time will be greatly saved.

★Fujian Suxinwang New Energy Co., Ltd. is a large-scale comprehensive international enterprise which integrates research and development, design, production and operation services. In recent years, in response to market demand, SUxinwang company has introduced the research and development, design, production and installation technology of cutting-edge plastic building templates, and launched a new generation of plastic building formwork with the combination of sales, leasing and construction. Compared to traditional templates, it has superior performance ,which are environmentally friendly materials. It is widely used in construction engineering, water conservancy and hydropower construction projects, bridges and tunnel projects, etc. It is a high-tech enterprise that realizes "to replace wood with plastic, to win wood, to save energy and protect the environment".

★Based on the principle of "survive by quality and innovation as concept", the company will continue to carry forward the spirit of "seeking truth and innovation,forging ahead",constantly produce environmentally friendly, energy-saving and high-quality new products and make a bigger contribution for the construction formwork business.

Workshop

★ When roof is laid with a plastic building formwork, 15mm thick plastic buildingformwork is used. According to the thickness and height of the wall, the 15mm thick plastic formwork can be used when the shear wall vertical mold.

★Distance between batten:

1. Plastic formwork is provided for supporting roof : distance between batten is determined according to the thickness of floor concrete.Under normal construction conditions, the thickness of floor less than 0.15 meter , distance between batten (center distance) is 200-250 mm.

2. Plastic formwork is provided for supporting shear wall: Adjust the distance between batten according to the height and thickness of the wall.Taking the height of 2800mm and the thickness of 300mm of the wall as an example, When the 15mm thickness formwork is adopted, the vertical subrib spacing is 150mm, if the shear wall and column width is more than 1 meter, a fixed frame must be added.

★ There is no gap between the shear wall and the column mold. The corner (the bottom of the wall) must have batten to connect the beam,the wall and the formwork.When shearing the wall vertical mold, it must be assembled into a whole piece and then hoisted, and then flattened for easy reduction.

Light labor intensity and good molding effect. When the plastic formwork nails the nail, it must be 15~30mm away from the edge of the formwork.

When the nail is moderately strong, the length of the nail is generally 40 to 50 mm, and should not be too long or too short.

★The wooden floor of the beam must have a 1.5 cm stop, and the wall plate stands on the wooden square to prevent leakage and save wallboard materials.

Advantage Comparison

★The size can be customized,no need for on-site cutting,reduce waste of material and save costs of material.

★The surface is smooth, no need to use a release agent, reduce the cost of the release agent.

★The number of turnovers reached more than 40 times, greatly reducing the cost of the total formwork material.

★No construction waste is generated, 100% full recycling, greatly reduce the cost of subsequent site management.

★Easy to disassemble, no on-site processing, shortened construction period and greatly reduced labor costs.